Testing And Tagging: What You Need To Know

Have you ever wondered how safe the electrical equipment in your workplace truly is? Electrical safety is critical in any business setting, yet it often goes overlooked until a problem arises. Testing and tagging your electrical appliances is not just a precaution—it’s a key measure to ensure the safety of your staff and the smooth operation of your equipment. Here’s a closer look at why and how this process should be part of your routine maintenance.

Understanding Testing And Tagging: An Overview

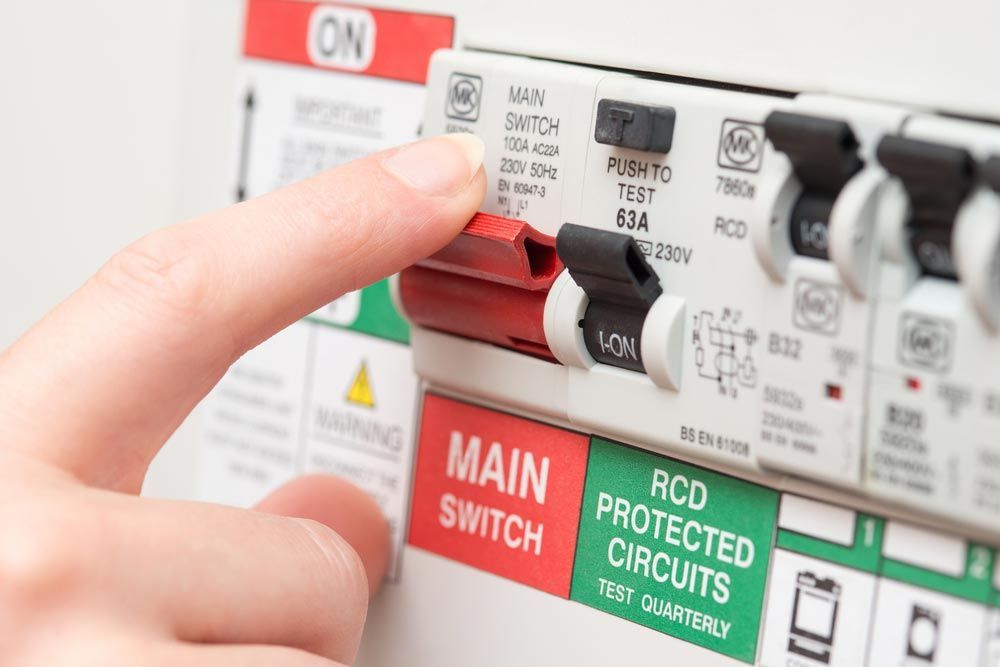

Testing and tagging is the process of inspecting and labelling electrical appliances to ensure they meet safety standards. This routine check is essential for maintaining a safe workplace environment.

What are Testing and Tagging? Testing and tagging involve a visual inspection followed by various electronic tests to verify an appliance’s safety.

Why is it Necessary? Regular testing helps identify potential electrical hazards before they lead to accidents or equipment failure.

The Importance of Regular Testing and Tagging for Safety

Regular electrical testing and tagging are essential for any business that relies on electrical equipment. This proactive measure ensures compliance with Australian safety regulations and enhances the reliability of your equipment, minimising downtime due to failures and accidents.

How Testing And Tagging Can Prevent Electrical Hazards

Recognising potential hazards before they become major issues is a key benefit of regular testing and tagging. Here’s what to consider:

- Identify Faulty Wiring: Early detection of frayed or damaged wires can prevent fires and other accidents.

- Spot Poor Performance: Regular checks help identify appliances that are not performing optimally, which can lead to energy inefficiencies and potential hazards.

- Ensure Safety Compliance: Regular testing keeps your equipment updated with the latest safety standards, protecting your staff and your business from legal repercussions.

Legal Requirements For Testing And Tagging

The requirements for testing and tagging electrical equipment are specified under the AS/NZS 3760 standard, which outlines the process and frequency needed to maintain safety compliance.

Who Needs to Comply? All Australian workplaces are required to adhere to these standards, especially those that use portable electrical equipment in high-risk environments.

Frequency of Testing The frequency of testing varies depending on the type of equipment and the environment it is used, ranging from three months to five years.

Step-by-Step Process Of Testing And Tagging

The process of testing and tagging involves several key steps:

- Visual Inspection: Checking for obvious signs of damage or wear.

- Electric Testing: Using specialised equipment for earth continuity, insulation resistance and polarity.

- Tagging: Attaching a durable, weather-resistant tag that records the test date and the next due test.

- Record Keeping: Maintaining a log of all tests for compliance and maintenance schedules.

Stay Compliant And Safe: Schedule Your Testing And Tagging Now!

Regular electrical testing and tagging are a critical component of maintaining workplace safety. At Peter Gow Electrical, we understand the importance of ensuring your workplace meets the highest electrical safety standards. Our team is equipped to provide thorough electrical testing and tagging services, ensuring that your equipment operates safely and efficiently. By choosing us for your electrical maintenance needs, you’re complying with workplace safety regulations and enhancing the overall safety and productivity of your operations. Reach out to us today to learn more about our services and how we can assist you in ensuring your electrical safety compliance.